Stable Supply Drives Buyer Priorities

In 2025, global importers increasingly focus on brake parts and steering assemblies with predictable performance and consistent delivery. Workshops and distributors now prioritize parts that reduce rework and downtime. Reliability in core components becomes a deciding factor when selecting suppliers.

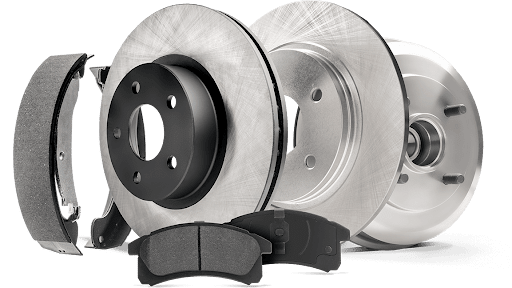

Key products attracting attention include:

Front Brake Disc for Haval H5

Link:https://bilinkglobal.com/product/front-brake-disc-3103102-k02-haval-h5/

Left Front Steering Knuckle Hub with Brake Assembly for Haval H6

Link:https://bilinkglobal.com/product/left-front-steering-knuckle-hub-brake-assembly-3001100xgw01a-haval-h6/

Both parts exemplify buyer demand for precise fit, durable materials, and clear technical documentation.

Fast-Moving Components Stay Critical

According to AutoParts News, fast-moving components such as brake discs, hubs, and suspension parts are increasingly prioritized by importers(source: https://www.autopartsnews.com/global-demand-report).

Inventory optimization for these fast-moving parts ensures uninterrupted service and supports seasonal sales peaks. Distributors who can reliably supply these components gain a competitive advantage.

Digital Verification Enhances Supplier Confidence

Aftermarket Journal reports that over 70% of buyers perform digital verification steps before onboarding new suppliers(source: https://www.aftermarketjournal.com/2025-sourcing-study).

These steps include:

-

Component testing and certification checks

-

Factory and warehouse photos

-

Packaging and batch record audits

-

Reputation assessments across markets

Digital verification reduces risks and ensures consistent supply of chassis parts and brake parts for importers.

Transparent Pricing Strengthens Long-Term Partnerships

Clear cost breakdowns for brake discs, knuckle hubs, and assemblies help buyers forecast inventory and budget accurately. Mid-sized importers now prefer suppliers who provide predictable MOQs and stable pricing. Transparency builds trust and strengthens long-term sourcing strategies.

Trust-Building Insight for Buyers

To secure reliable supply, importers and workshops should confirm:

-

Complete documentation for every brake part batch

-

Accurate test data for steering assemblies

-

Standardized packaging for export

-

Consistent material and mold quality

-

Updated technical specifications for every shipment

These measures reduce operational uncertainty and ensure uninterrupted service efficiency.

Related product:

Related Post

Data Illusion Series – Part 3: Big Supplier vs Stable Supplier: Why Size Does Not Guarantee Stability in the Auto Parts Supplier Market

Data Illusion Series – Part 2: Low Price vs Low Risk in the Aftermarket Auto Parts Supplier Market

Data Illusion Series – Part 1: Sales Growth vs Inventory Health: Why High Volume Can Be Dangerous

Inventory Structural Dynamics: Why Stock Problems Are Rooted in Early Decisions, Not Operations